solutions for

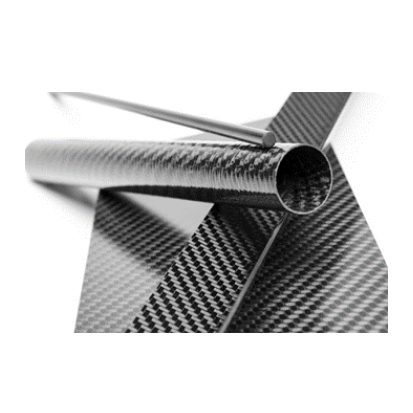

Composite / Graphite materials

The growth of carbon-fiber applications has driven new machining technologies for composites. Machining techniques, cutting tool designs and work holding solutions have been refined but the biggest area is cutting tool design, with a growing range of tooling companies introducing new designs to overcome the problems of machining composites, which behave very differently to metals. Layers, or plies, of fiber and resin bonded together react differently when placed under the force of a cutting tools.

The main composite machining types are drilling and edge trimming. Each present different challenge.

Composites are a combination of components. composites are materials made by combining two or more natural or artificial elements (with different physical or chemical properties). The component materials don’t completely blend or lose their individual identities; they combine and contribute their most useful traits to improve the outcome or final product.

Fiber-reinforced composite materials have gained popularity (despite their generally high cost) in high-performance products that need to be lightweight, yet strong enough to take harsh loading conditions such as Aerospace components (tails, wings, fuselages, propellers), Boats, Automotive including Racing car bodies, wide varieties of Civil use : Wings of wind turbines, Construction (bridges, Roads..) leisure & Sport (bicycle frames, racing car bodies, fishing rods, storage tanks, swimming pool panels, baseball bats and many others….

Cutting, routing and drilling are important processing steps for machining composite parts. The most common methods for machining composites are Diamond abrasive Grits tools.

Using Diamond Abrasive tools offer much longer life, in some cases, hundreds of times longer,

Besides long life, diamond tools also offer dimensional stability while machining composite materials. diamond drill or router bit diameter remains more consistent,

” M.D.T INDUSTRIAL” proud to offers endless solutions machining Diamond technologies for composites.

Part of Schneider Group, MDT Industrial is a worldwide manufacturer of diamond/CBN abrasive grits tools.

Since 1990, MDT Industrial specializes in design and manufacture of precision diamond abrasive grits tools for grinding, cutting, deburring, drilling, trimming and polishing of abrasive materials such as: Composites, Honeycomb Composites, Graphite & Kevlar, Reinforced Plastics, Ceramics, Fiberglass, High Temperature Alloys, Tungsten Carbide, Inconel and more.