QUALITY ASSURANCE

Technologies

QUALITY ASSURANCE

QUALITY ASSURANCE

” M.D.T INDUSTRIAL TOOLS” quality policy defines a holistic approach towards customer’s satisfaction and benefit. While maintaining ISO 9001:2015, ISO 13485:2016 ” M.D.T INDUSTRIAL TOOLS ” saves no efforts in keeping its manufacturing products on the first line of quality and Excellency with presale, sale and post-sale support.

Diamond-Tools manufacturing is done using the most modern manufacturing equipment to obtain best repeatability and reproducibility while using the highest quality diamond, carbide and steel grades.

With professional and continuously trained staff ” M.D.T INDUSTRIAL TOOLS” maintains in process quality control and final inspection control on the most modern measuring equipment, allowing strict and accurate measurements and digitally documented reports.

” M.D.T INDUSTRIAL TOOLS ” delivery lead times are faster than market standard while keeping highest OTD and lowest return rates.

Professional application engineers support presale efforts to

Diamond-Tools manufacturing is done using the most modern manufacturing equipment to obtain best repeatability and reproducibility while using the highest quality diamond, carbide and steel grades.

With professional and continuously trained staff ” M.D.T INDUSTRIAL TOOLS” maintains in process quality control and final inspection control on the most modern measuring equipment, allowing strict and accurate measurements and digitally documented reports.

” M.D.T INDUSTRIAL TOOLS ” delivery lead times are faster than market standard while keeping highest OTD and lowest return rates.

Professional application engineers support presale efforts to

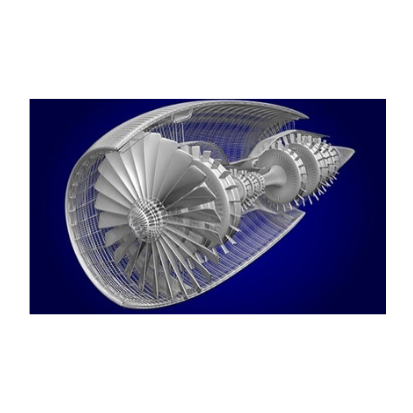

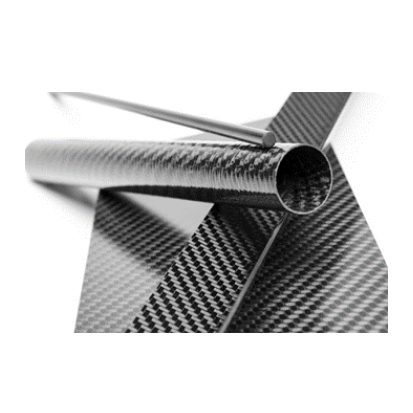

Solutions for Abrasive materialS

MDT designs and delivers advanced cutting solutions for all abrasive materials, from standard to customized engineered solutions, you can rely on our experience

Part of Schneider Group, MDT Industrial is a worldwide manufacturer of diamond/CBN abrasive grits tools.

Since 1990, MDT Industrial specializes in design and manufacture of precision diamond abrasive grits tools for grinding, cutting, deburring, drilling, trimming and polishing of abrasive materials such as: Composites, Honeycomb Composites, Graphite & Kevlar, Reinforced Plastics, Ceramics, Fiberglass, High Temperature Alloys, Tungsten Carbide, Inconel and more.